Understand the science so you don’t get burned.

What is SPF?

SPF stands for sun protection factor and it is a measure of how well a sunscreen will protect your skin from the sun’s harmful UV rays. Sunscreens absorb or reflect UV radiation from the sun before it penetrates your skin and damages your skin.

If you want to know the true SPF meaning – including how long does SPF last – you can find all the answers here!

SPF Levels

Most sunscreens on the market today have an SPF of 15 or higher. Higher SPF numbers are supposed to indicate greater protection against UVB rays, but it’s not as simple as that.

The level of protection does not increase proportionally as the SPF value increases.

Here’s what you need to know about SPF levels and their effectiveness:

- SPF 15 blocks 93% of UVB rays

- SPF 30 blocks 97% of UVB rays

- SPF 50 blocks 98% of UVB rays

*Note that the SPF value only indicates the UVB ray protection. Only products labeled broad spectrum offer both UVA and UVB protection.

Basically, an SPF 50 sunscreen only gives you 5% more protection than SPF 15 sunscreens. The difference in the levels of protection between SPF 30 and SPF 50 sunscreens is only 1%.

Does Higher SPF Protect You More?

This is where things get complicated. The SPF number tells you how long the sun’s UV radiation would take to redden your skin when using the product exactly as directed. However, more often than not, people tend to underapply the product, thus toying with its effectiveness.

Using a higher SPF sunscreen doesn’t guarantee that you can stay longer in the sun without getting sunburned.

Another thing to keep in mind is that SPF testings are conducted in controlled environments, as we explain below. Under ideal conditions (like when conducting the testing in a laboratory), a sunscreen with higher SPF protection offers more protection against sunburn than comparable products with lower SPF values.

But, this is not how things work in the real world, in unpredictable and uncontrolled circumstances.

Ultimately, how long does SPF last and the level of protection it offers depend mostly on the sun’s intensity and the user’s willingness to apply the product as directed.

A higher SPF does not necessarily entitle better protection and can lead to a false sense of safety if the user is misinformed.

No matter the SPF level you choose, follow the golden rule of reapplication – every two hours. Even the highest SPF sunscreen will prove ineffective when it wears off. If you apply it generously and as directed, an SPF 30 sunscreen is just enough to keep you protected.

How is SPF Tested and Rated?

In order to receive an SPF rating, a sunscreen must go through two types of testing: in vitro or laboratory tests, and in vivo or clinical studies on human subjects.

In vitro testing uses controlled exposure of skin cells or tissue samples to ultraviolet light. The level of protection the sunscreen provides can then be measured. In vivo testing is conducted on human subjects who apply the sunscreen to their skin and then expose themselves to either artificial or real sunlight. The amount of UV radiation that reaches the skin is then measured.

It’s important to remember that this testing is done in a lab, not in the real world, so the results may not actually reflect how long it takes you to get a sunburn. The FDA doesn’t have a standard way of testing SPF, so there’s a lot of variation between manufacturers.

According to the FDA, SPF is a measure of how much solar energy (UV radiation) is required to produce sunburn on protected skin (i.e., in the presence of sunscreen) relative to the amount of solar energy required to produce sunburn on unprotected skin. As the SPF value increases, sunburn protection increases.

SPF is not related to a specific amount of sun exposure. This is because solar energy is not constant, there may be more solar energy at 12 p.m. than at 8 a.m.. SPF is a measure of the amount of solar energy, not time.

FDA’s Standardized Broad Spectrum Protection Test and Claims

All sunscreens advertised as SPF or broad spectrum today have passed the FDA’s standardized test. While the standardized SPF test ensures the sunscreen protects against UVB rays, the broad spectrum test helps consumers stay informed on not only the UVB but also the UVA protection a sunscreen offers. Only those products that pass the test may be labeled as broad spectrum.

Allowed Claims

Broad spectrum sunscreens with a minimum SPF value of 15 can claim to prevent signs of aging and to reduce the skin of skin cancer, while those with lower SPF value can only claim to help prevent sunburn.

Waterproof, sweatproof, and sunblock claims are not allowed as they’re misleading and serve only for advertising purposes without a scientific background. Unless a manufacturer submits enough evidence and data, products can’t claim to provide sun protection for more than two hours.

If a manufacturer wants to make a water resistance claim, the product must undergo standard testing and the front label must indicate if the sunscreen is effective for 40 or 80 minutes of activity, be it swimming or sweating. If a product doesn’t meet the water resistant requirements, the manufacturer must instruct the consumers to use a water resistant sunscreen when swimming or sweating.

All sunscreens must include ‘Drug Facts’ information.

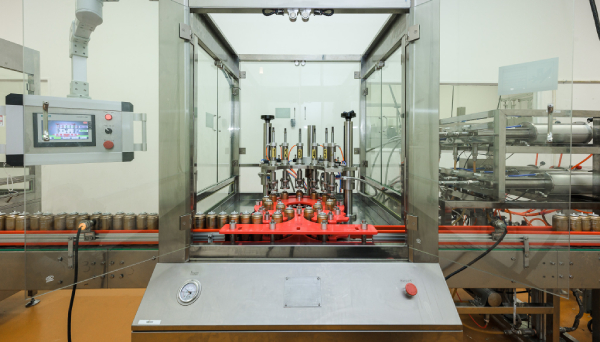

Our SPF Testing Protocols

InSpec Solutions substantiates all claims for every formulation based on targeted regulatory requirements. We conduct all testing from in vitro, in vivo, critical wavelength, broad spectrum, to water resistance. All formulations undergo Accelerated stability studies to help determine shelf-life.

All formulations which become commercialized undergo thorough Validation protocols to ensure homogeneity, and adherence to all product specifications. All batches are tested for physicals, analytical, and micro testing prior to release.

Focusing on sunscreen efficacy testing, InSpec testing capabilities include:

- SPF efficacy (FDA Final Rule, ISO 24444, COLIPA, and others)

- Water Resistance efficacy (FDA Final Rule, COLIPA, AUS/NZ, and others)

- Broad Spectrum efficacy (FDA Final Rule, ISO 24443, and others)

We can also test for ISO 24444:2010 STATIC + COLIPA 2005 40 or 80 MIN WR, or AS/NZS 2604:2012 STATIC + 40, or 80 MIN WR or AS/NZS 2604:2021 STATIC + 40 or 80 MIN WR.

SPF Product Options

When it comes to sun protection, there are a lot of products on the market that claim to offer protection from the harmful UV rays. Aside from sunscreens, another popular option for sun protection is beauty products enhanced with SPF.

Many foundations, BB creams, and CC creams now come with SPF built in, so users can get the coverage they need while also protecting the skin from the sun.

When trying to choose between a sunscreen and a moisturizer, sunscreen should always come first. But, if you’re looking for both, the best option is to choose a broad spectrum moisturizer that has SPF in it.

If you partner with us, you can create an SPF product that pushes the boundaries of SPF product manufacturing and offers numerous skin benefits with unparalleled sun protection.

InSpec Solutions manufactures all kinds of products in different formulations, including creams, sticks, lotions, serums, gel, balms, and tints with higher or lower SPF levels.

Of course, sunscreens remain the best SPF product option. Sunscreens come in a variety of formulas, including gels, sprays, and lotions. But, they’re not all made the same!

Aerosol Canister vs Bag-on-Valve Technology & Increased Safety of Spray Sunscreens

Spray sunscreens have been gaining a lot of traction lately mostly because they’re easy to apply but still offer the same level of protection as any other sunscreen texture.

When packaging spray sunscreens, manufacturers have two options:

- Bag-on-Valve

- Conventional Aerosol Canister

Think of Bag-on-Valve as an upgraded version of aerosol cans.

Bag on Valve technology relies on a multi-level protective system that incorporates the basic components of a conventional aerosol canister – and then some. It utilizes a tin plated steel or aluminum can and four-layer vacuum pouches which aerosol canisters don’t. As a result, BoVs are proven to have a better sealing performance.

Additionally, Bag-on-Valve technology is becoming increasingly popular due to the fact it safeguards the sunscreen’s integrity. As the product itself is separated from the propellant (in a bag) there’s little to no risk of oxidation, thus upholding the product’s purity.

When it comes to aerosol canisters, the product and propellant aren’t separated, imposing a risk of contamination by bacteria and other gasses.

However, conventional aerosol canisters are safer to use than cream sunscreens which have higher chances of being contaminated. If your manufacturing goals are aimed towards a sunscreen that’s easy and safe to apply, a spray sunscreen checks all the right boxes whether you opt for a conventional aerosol canister or bag-on-valve technology.

If you’re uncertain which way to go, our team is here to answer all your questions and guide you through your sunscreen manufacturing journey, whether you’re looking for contract manufacturing or private label options.

Oxybenzone and Octinoxate-Free Sunscreens are the Future & InSpec Solutions’ Focus on Mineral Sunscreens

In an effort to protect the environment and human health, many companies are getting rid of oxybenzone and octinoxate, two common ingredients in sunscreens. These ingredients have been shown to be harmful to coral reefs, so their removal is a major victory for environmentalists.

Aside from harming the environment, oxybenzone is also an endocrine disruptor known to interfere with human hormones. Research shows that this chemical may cause health problems.

Sunscreens containing oxybenzone, octinoxate, or other chemical filters such as avobenzone or octisalate are known as chemical sunscreens. Working like a sponge, these ingredients absorb UV radiation to prevent it reaching the skin and doing it harm.

Chemical sunscreens are known to quickly absorb and dry without leaving a white cast, but they also impose a huge risk on human health and the environment.

Although the FDA hasn’t banned the usage of oxybenzone and octinoxate, InSpec Solution is focused on manufacturing mineral sunscreens that don’t contain oxybenzone and octinoxate, thus paving the road to a safer sun protection – for both people and the environment.

The active ingredients in mineral sunscreens are more environmentally friendly and they’re not as harsh on the skin. Using two natural ingredients – zinc oxide and titanium dioxide – mineral sunscreens sit on the skin and protect it by reflecting away UV rays. Since mineral sunscreens are not absorbed into the skin, there’s no way for harmful ingredients to enter your body.

However, many consumers find sunscreens containing oxybenzone and octinoxate – also known as chemical sunscreens – more effective, so we offer both.