Bag on valve technology is designed to improve products in various industries, including the cosmetic and Over the Counter Drug industry. This innovative technology offers a cleaner packaging solution for aerosol products. It allows a more versatile and practical use than the traditional aerosol packaging technology and will enable products to be sprayed upside down, something virtually unheard of in the industry.

On top of that, bag on valve technology offers various production and distribution benefits. Keep reading to learn all the ins and outs of the bag on valve technology.

How Does Bag on Valve Technology Work?

Bag on valve technology offers a new barrier packaging solution for aerosol products. Barrier packaging means that the product substance and the gas are separated in their respective containers. As a result, the propellant isn’t released when the product is used, thus creating safer and more environmentally-friendly aerosol packaging.

In addition, the product separation preserves its integrity and purity. For this reason, any skincare product can be dispensed using the bag on valve technology, including creams, gels, and liquids. The only exception is products that need to be shaken before use.

Besides the substance and propellant, the bag on valve system consists of several other aerosol elements:

- Bag on Valve

- Lined can (PAN or epoxy coating)

- Actuator/cap

The foil-based bag is welded to the valve with a multi-layer film laminate and inserted inside the can. Then, the bag is packed with the product, while the gas or air fills the space between it and the can. When a consumer presses the actuator, the pressurized can will squeeze the bag, thus dispensing the product.

How to Choose the Parts of the Bag on Valve System?

Assembling the best bag on valve system for your product comes down to the product’s features, the desired performance, and estimated cost.

Valves

The valve used for bag on valve and aerosol packaging is available in both female and male versions.

These valve types primarily differ in stem construction. A female valve retains half of the stem while the other half is on the actuator. As a result, aerosol cans with a female valve can be filled much faster than their male-valve counterparts. However, this convenience also means that female valves come at a higher price.

Bag

Most products in the bag on valve packaging use a four-layer vacuum bag. Each layer is connected with an adhesive and serves a specific purpose, guaranteeing mechanical and chemical resistance, regardless of the filled product. The development of these laminated bags has been backed by thorough research, so it’s not surprising they are FDA-approved.

Regarding the vacuum bag considerations, the primary decision is choosing an adequate bag size. Bags used for bag on valve systems are available in an extensive size range. Also, the bag can have three rather than four layers, depending on the product requirements.

Bag on Valve Formulations

One of the main advantages of the bag on valve systems is that they support both liquid and viscous products. The latter consistency makes this system perfect for the cosmetic industry, allowing the aerosol substance to take a gel, cream, post-foaming, or ointment form. In addition, this packaging works well with powders and thick products not typically associated with this type of packaging.

Propellant

Compressed air and nitrogen serve as propellants in the bag on valve technology. Besides being environmentally friendly, these affordable gasses allow consumers to use the product at any angle and with minimal noise.

Cans

Aluminum and tin are the two materials most commonly used for manufacturing aerosol cans in the bag on valve system. The material doesn’t affect the product type inserted into the can.

The primary differences between aluminum and tin aerosol cans are cost and performance. Namely, aluminum cans typically cost more but offer a much cleaner and healthier packaging solution.

In contrast, tin cans are usually highly affordable but rust easily, making them unsuitable for preserving product quality in the long run.

The Benefits of Bag on Valve Technology

The bag on valve technology offers numerous benefits for manufacturers, consumers, and the environment alike. Here are the most substantial production and distribution benefits of this unique system.

The Propellant Doesn’t Affect Product Formulation

Unlike traditional aerosol packaging, the bag on valve system doesn’t require the gas and the substance to mix when the product is used. As a result, the product formulation doesn’t have to be altered to accommodate it. Besides being practical, this versatility also keeps the production costs down.

The Vacuum Bag Allows a Longer Shelf Life for Oxygen-Sensitive Products

The technology behind the FDA-approved four-layer vacuum bags makes the bag on valve systems optimized for sterile and oxygen-sensitive products. This property maximizes the product’s shelf life.

The Bag on Valve System Offers an Efficient Filling Process

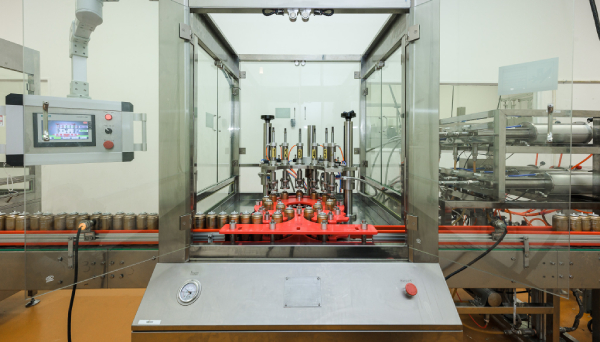

The bag on valve systems rely on advanced automatic or semi-automatic filling machines. These high-tech machines have significantly improved the manufacturing process, cutting down costs and creating a finished product with improved quality. Since the product substance is entirely separated from the can body, the filling process avoids corrosion, making it much more efficient.

The Bag on Valve System Uses Standard Actuators and Cans

Although bag on valve systems put a twist on the traditional aerosol can mechanism, the can itself is pretty standard. The same goes for the aerosol actuator. So, you don’t have to design non-standard cans and actuators, thus saving time and money.

The Bag on Valve System Offers Multiple Marketing Avenues

The bag on valve products are easily marketable to skincare pros and beginners alike. This packaging resolves most of the complaints customers have about traditional aerosol cans. When marketing the products, you can use the following qualities to your advantage:

- The product can be emptied up to 100%.

- The product offers a controlled and even spraying pattern for optimal results.

- The product doesn’t require a continuous pumping motion.

- The product makes minimal spray noise.

- The product is more environmentally friendly than traditional aerosol products.

Why Switch to Bag on Valve Spray Technology From Traditional Aerosol Technology?

The marketing talking points are based on the advantages of the bag to valve products over their traditional aerosol counterparts. In the past, the traditional aerosol spray technology was prevalent due to a lower cost and insufficient development of the bag on valve technology. Since both aspects have changed, bag on valve technology is a clear winner between the pair and the future of aerosol packaging. Let’s discuss why that is.

Sealing Performance

Bag on valve packaging is a complex system that offers multiple protective properties, including four-layer vacuum bags. In contrast, traditional aerosol packaging doesn’t provide any bag protection for the material within the can, thus delivering poor sealing performance.

Material Purity

The product substance within a bag on valve product is completely separated from the gas and protected by a food-grade vacuum bag with excellent sealing properties. As a result, the material is guarded against oxidation, cold, heat, light, and other secondary pollution, thus preserving its purity.

On the other hand, the propellant and material are mixed within traditional aerosol cans. Besides the gas affecting the material’s purity, the lack of appropriate sealing allows bacteria to enter and pollute the product, thus deteriorating the material quickly.

Spray Effect

A bag on valve spray guarantees a uniform and continuous spray effect, easily absorbing the product into the skin. The same can’t be said for traditional aerosol sprays that typically have a significant impact force, wasting the product and diminishing the absorption properties.

Spray Convenience

A bag on valve spray contains no sediments and can be sprayed without pressing the actuator multiple times. On top of that, there’s no need to position the can as these products enable a 360-degree angle spray.

Traditional aerosol products typically must be shaken before use due to sediment deposition. Using these products requires pressing the actuator multiple times and holding the can at a fixed horizontal angle.

Utilization Rate

Because of the cost of skincare products, not a single drop should go to waste. The bag on valve system allows the product to be used up to 100%, leaving no residue as traditional aerosol products do.

Safety Performance

The bag on valve products don’t contain flammable propellants, which is the case for most traditional aerosol products. Therefore, the former products can’t cause a fire or an explosion. These properties make using the bag on valve spray products considerably safer.

How Can the Bag on Valve Technology Be Applied in the Cosmetic Industry?

The bag on valve technology allows you to use the same packaging type for products with varying consistencies. The only requirement is that the product’s viscosity allows passage through the valve stem.

Besides being more practical and cost-effective, this uniformity also helps increase product line identification, making your products more visible on the shelf.

Bag on valve packaging can be used for various skincare products:

- Sun care and regular creams

- Lotions

- Facial washes

- Toners

- Gels

- Solutions

- Self-tanning sprays

The Future Is in the Bag

The bag on valve technology has revolutionized the aerosol industry. This unique technology provides better opportunities for innovations in product design and use. Furthermore, it has resolved all customers’ issues with traditional aerosol filling, guaranteeing they will flock to product lines featuring the bag on valve technology.

Hopefully, this guide has helped you learn everything you need to know about this technology and its many benefits. This thorough understanding of the bag on valve systems should help you decide if this is the best choice for your products.